Why Should You Prioritize Traceability When Selecting an Electronic Components Supplier

Selecting the right supplier for electronic components is more than just about price or availability. One of the most critical aspects that procurement teams must prioritize is quality control, specifically the traceability of products. Traceability refers to the ability to track and document the history, location, and manufacturing processes of a product at every stage of its lifecycle. In electronic components, having a robust traceability system is crucial because it ensures that any quality issues can be quickly identified, traced back to their root cause, and efficiently resolved.

Why Traceability Matters in Electronic Components?

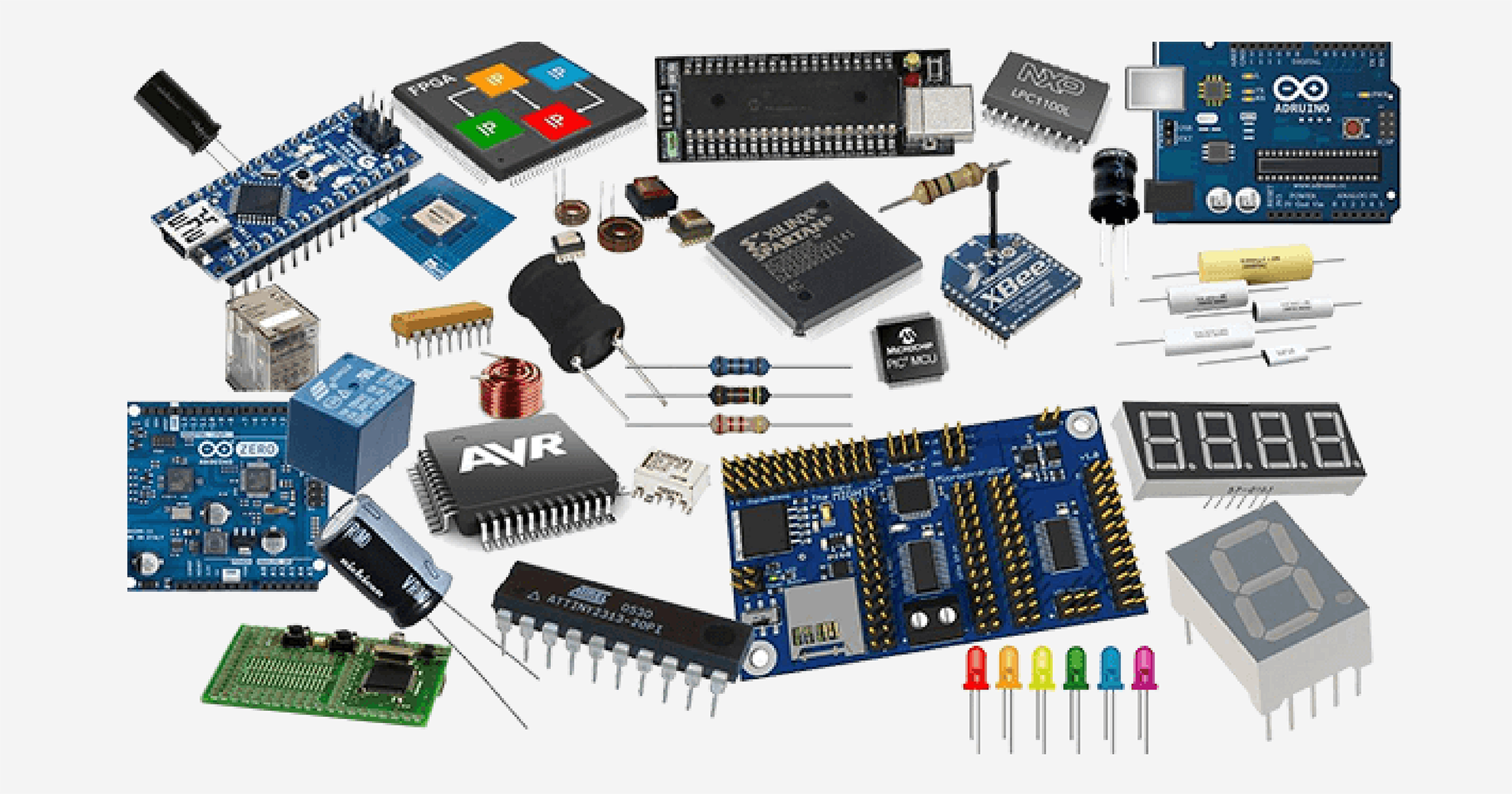

Electronic components, whether they are resistors, capacitors, semiconductors, or connectors, form the backbone of nearly every modern technology. As these components are integrated into more sophisticated and critical applications (e.g., medical devices, automotive systems, and telecommunications), the risk of quality failures increases. Even a minor fault can lead to costly production delays, safety concerns, or product recalls.

Traceability ensures that when quality issues arise, they can be linked back to specific batches or even individual units of production.

Efficient Problem Resolution

Without traceability, identifying the root cause of a quality problem can be a slow and costly process. Traceability systems allow procurement teams to pinpoint the exact batch or production line where a defect originated. This can drastically reduce the time needed to resolve issues and prevent defective products from reaching consumers. In the case of a large-scale failure, traceability can also help isolate and remove affected components from the supply chain before they cause significant harm.

Compliance and Industry Standards

Many industries, such as automotive, aerospace, and medical devices, have strict quality assurance and compliance standards. Suppliers that offer traceability can provide the necessary documentation and verification of the materials, processes, and inspections used in the manufacturing process. For instance, if a semiconductor fails in a critical medical device, regulators will require traceability data to identify the affected batches and suppliers involved. A transparent traceability system helps ensure compliance with regulatory bodies and demonstrates a supplier's commitment to maintaining high standards.

Preventing Counterfeit Components

Counterfeit electronic components are a growing concern in the global supply chain. In some cases, counterfeit parts may have similar appearances to genuine products, but they often fail to meet safety or performance specifications. A reliable traceability system can act as a deterrent against counterfeit parts entering the supply chain. By ensuring that every component is properly documented, verified, and tracked, suppliers can offer proof of authenticity, giving procurement teams confidence in the integrity of their purchases.

Improving Supplier Accountability

Suppliers with strong traceability systems demonstrate accountability and transparency. These systems show that the supplier is not only committed to quality control but is also proactive in addressing potential issues. When a supplier has a clear and accessible traceability system in place, it reflects their dedication to continuous improvement and customer satisfaction.

How to Assess Traceability When Choosing a Supplier?

When evaluating suppliers, procurement teams should prioritize those with a clear and effective traceability system. Here are some key elements to look for:

Batch and Serial Number Tracking: A robust traceability system should allow tracking by batch number, serial number, or lot code. This enables quick identification of affected products if a quality issue arises.

Documentation and Reporting: Ensure that the supplier provides clear and comprehensive documentation, including reports on the manufacturing process, inspections, certifications, and any quality control measures taken.

Technology Integration: A modern traceability system will often integrate with other supply chain management tools, such as Enterprise Resource Planning (ERP) systems, allowing seamless tracking of products from production to delivery.

Transparency and Responsiveness: The supplier should be willing and able to provide traceability data when requested, and have a clear process for addressing quality issues swiftly.

Conclusion

As the electronics industry continues to innovate at a rapid pace, ensuring the quality and reliability of components is more critical than ever. Traceability in quality control provides a crucial safety net, allowing procurement teams to quickly identify the source of any issues and take corrective actions without disrupting the entire supply chain. It is an indispensable part of maintaining both operational efficiency and product integrity.

At ICHOME, we prioritize comprehensive traceability across all our products. Our sophisticated tracking system ensures that every component we supply is thoroughly documented, providing our clients with confidence that they are receiving high-quality, well-vetted products. With ICHOME, you can be assured that your sourcing decisions are backed by a commitment to precision, transparency, and swift resolution of any quality concerns.