BOM Cost Down

What is bill of materials (BOM)?

BOM is a detailed list of the parts, raw materials and related information required for a product, and is an important document in the manufacturing and electronics industries.

The cost of BOM is composed of raw materials, labor, tools and equipment, packaging, transportation and logistics, quality control, taxes and tariffs, supplier costs, R&D value engineering and research costs, waste or scrap, software and licensing, testing, and compliance, as well as all marketing and promotions.

For electronic products, the BOM including:

Active components – Integrated circuits, transistors, diodes, LEDs, etc.

Passive components – Resistors, capacitors, inductors, transformers, etc.

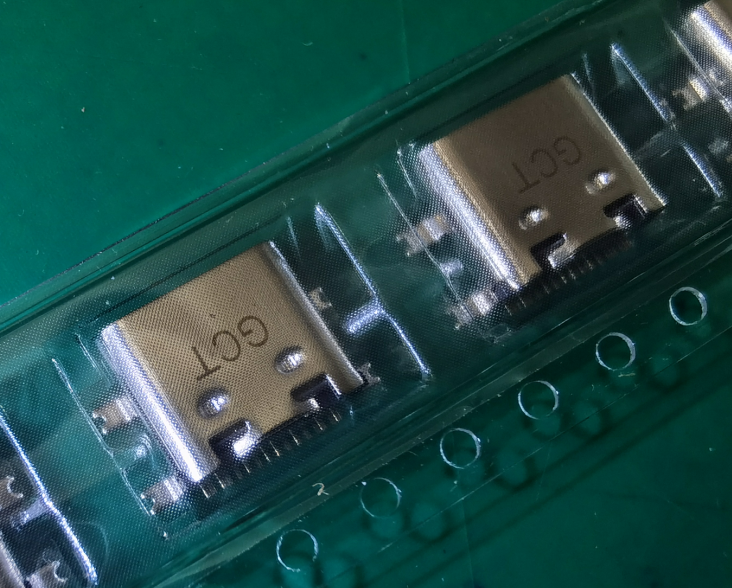

Electromechanical parts – Connectors, switches, sensors, motors, etc.

PCBs – Bare printed circuit boards and assemblies.

Miscellaneous – Hardware, terminals, standoffs, fasteners, wiring, etc.

The BOM provides key information needed for costing analysis including:

Part numbers – Unique identifiers for each item

Descriptions – Details on the specific component

Quantities – How many of each item are required

Manufacturers – Vendor source for procuring each item

Unit price – Cost per item (a key input to total BOM costing)

Why BOM Costing is Important?

Accurately calculating BOM cost is essential for several reasons:

Defines production costs: It determines the direct costs to manufacture the product.

Enables accurate pricing: Ensures pricing covers production costs plus margin, avoiding losses.

Aids sourcing decisions: Provides insight into material costs to evaluate supplier options.

Facilitates cost reduction: Highlights opportunities for savings through substitutions, design changes, or vendor selection.

Supports cost tracking: Serves as a baseline to monitor material costs during production.

Identifies cost risks: Flags high-cost or uncertain items for contingency planning and attention.

4 Ways to Make BOM Cost Down

Consider sourcing early

Optimize production costs from the earliest days of design. Choose slim and smaller components, which will be more cheap. The size, weight, volume, and cost of a product are all interrelated.

Cost Transparency

Collect your existing bill of materials (BOM) data, production information, understand your product and components. Analyze the cost structure of your BOM, determine the individual cost of each component, and cut costs without sacrificing quality.

Exploring Cost-Saving Opportunities

Alternative Component Research: Our team investigates alternative components that offer similar functionality but potentially lower costs. We prioritize reliable and readily available options.

Perform risk analysis

Identify high cost components and items with uncertain or volatile pricing for management focus. Review component costs against quotes or market pricing continually throughout product lifecycles to maintain accuracy.

With ICHOME's 20 years of experience in the electronics industry. Let us help you deeply analyze BOM to optimize production costs, exploring cost-saving opportunities.